How Dynamics 365 SCM Improves Warehouse and Inventory Management

Introduction: Understanding Dynamics 365 Warehouse Management

Dynamics 365 warehouse management is a game-changer for modern businesses aiming to streamline warehouse and inventory operations. In today’s fast-moving supply chain world, having real-time insights and precise control over stock levels is essential. Microsoft Dynamics 365 Supply Chain Management (SCM) offers end-to-end visibility that allows organizations to manage warehouses, automate tasks, and make data-driven decisions.

The traditional way of managing warehouses with spreadsheets and manual records has become outdated. Companies now require a robust, cloud-based solution to handle everything from inbound logistics to outbound shipments. Dynamics 365 SCM delivers this by merging warehouse automation, inventory control ERP, and logistics operations management into one intelligent platform.

In simple terms, it helps warehouse managers control stock efficiently, reduces manual labor, and improves productivity through automation and integration. When you combine this with AI-powered insights, it not only tracks inventory but predicts trends, allowing businesses to stay one step ahead of demand.

The Role of Dynamics 365 in Smart Inventory Control ERP

One of the strongest capabilities of Dynamics 365 SCM lies in its integration as an inventory control ERP system. Unlike conventional ERP software that simply tracks goods, Dynamics 365 SCM provides dynamic inventory optimization. It records every movement of goods — from raw materials entering the warehouse to finished products shipped to customers.

By connecting procurement, production, and sales processes, the system ensures a seamless data flow. For instance, when inventory levels fall below a set threshold, the system can automatically generate purchase orders. This automation reduces dependency on manual input and eliminates errors often caused by human oversight.

Furthermore, the inventory control ERP module in Dynamics 365 empowers businesses to use real-time analytics. With instant access to data like stock levels, item locations, and order statuses, warehouse teams can make faster and more accurate decisions. This leads to fewer stockouts and improved order fulfillment rates.

Most importantly, Dynamics 365 SCM doesn’t just monitor stock—it strategically manages it. It uses AI-based forecasting to predict demand, allowing you to plan procurement and production more intelligently. That’s the difference between tracking and managing.

Core Features of Dynamics 365 Warehouse Management

The features of Dynamics 365 warehouse management make it a standout choice for businesses of any size. Some of the most beneficial include:

- Real-Time Inventory Tracking: Businesses get instant visibility into stock levels, movement, and availability.

- Automated Warehouse Operations: The system streamlines picking, packing, and shipping, reducing time and labor costs.

- Integration Across Departments: From finance to sales, every department accesses synchronized information.

- AI and Analytics: Predictive insights allow better forecasting, resource allocation, and performance evaluation.

The system supports advanced warehouse configurations like multiple storage zones, batch numbers, and lot control. It even helps with barcode scanning and RFID tracking, making stock management accurate and quick.

Moreover, by integrating with logistics operations management tools, Dynamics 365 SCM enhances end-to-end supply chain visibility. Managers can oversee inbound shipments, track transit updates, and schedule deliveries, all within one unified dashboard.

Enhancing Efficiency Through Warehouse Automation

Warehouse automation is one of the most valuable components of Dynamics 365 warehouse management. It redefines how businesses handle storage, picking, packing, and dispatching goods. Instead of relying on manual processes that consume time and increase human error, automation streamlines every step.

With Dynamics 365 SCM, warehouse automation becomes easier through features like automated replenishment, barcode scanning, and robotic picking integration. This allows businesses to process orders faster while maintaining higher accuracy. For example, the system can automatically assign the most efficient route for pickers inside the warehouse, saving both time and energy.

Automation also improves employee productivity. Rather than performing repetitive data-entry tasks, employees can focus on value-added activities such as quality checks and logistics coordination. This balance of human intelligence and machine precision creates a powerful warehouse ecosystem.

Additionally, warehouse automation in Dynamics 365 reduces downtime. Since tasks are managed digitally, errors like misplaced items or delayed order fulfillment become rare. Businesses can even integrate the system with smart devices, allowing for real-time updates and alerts. Whether a pallet needs relocation or an item runs out of stock, managers are instantly notified.

In India’s competitive business landscape, speed and reliability are critical. By combining automation with intelligent inventory control ERP systems, companies can handle growing customer demands effortlessly. Warehouse automation with Dynamics 365 SCM thus ensures consistent performance, scalability, and future-readiness.

Streamlining Stock Tracking in Dynamics 365

When it comes to stock tracking in Dynamics 365, precision is key. Every warehouse manager knows that a small tracking error can result in major inventory discrepancies. Dynamics 365 SCM eliminates these problems through real-time stock tracking powered by advanced analytics and IoT technologies.

Each product or component can be tagged using barcodes or RFID chips, allowing instant visibility of its movement within the warehouse. This technology-driven approach ensures that businesses always know exactly what’s available, where it’s stored, and when it needs replenishment.

Beyond physical tracking, Dynamics 365 SCM also connects stock data with other departments like purchasing, finance, and production. This integration allows seamless coordination between warehouse and business processes. For instance, when the warehouse updates stock levels, purchasing instantly receives alerts for low inventory. This synchronization helps prevent both overstocking and stockouts.

One major advantage of stock tracking in Dynamics 365 is its AI-driven demand forecasting. It not only monitors existing stock but predicts future needs based on past data and sales trends. This predictive capability supports just-in-time (JIT) inventory strategies—minimizing waste and optimizing warehouse space.

Ultimately, this feature empowers decision-makers with actionable insights. Whether it’s replenishment planning, product returns, or shipment tracking, Dynamics 365 SCM ensures total visibility and control over every inventory aspect.

Optimizing Logistics Operations Management with Dynamics 365 SCM

The role of Dynamics 365 SCM goes beyond warehouses—it extends to the entire logistics operations management framework. A business can only deliver efficiently if its logistics are optimized. Microsoft Dynamics 365 achieves this through end-to-end visibility, real-time route optimization, and collaboration tools.

It integrates transport management directly into warehouse operations. As soon as an order is packed, the system automatically selects the most efficient transport route based on delivery location, traffic data, and carrier availability. This reduces delivery times and fuel costs, enhancing overall operational efficiency.

Additionally, logistics operations management in Dynamics 365 ensures full transparency. Customers can track their orders in real time, while managers monitor the delivery process through dashboards. This feature significantly improves customer satisfaction and builds trust in the brand.

For businesses managing multiple warehouses or regional hubs, Dynamics 365 SCM offers centralized logistics control. It enables coordination between storage facilities, transport fleets, and suppliers. Even international shipments become easier to handle through multi-currency and multi-language support.

In short, Dynamics 365 SCM bridges the gap between warehouse and logistics, offering a holistic solution that optimizes operations, enhances visibility, and reduces costs.

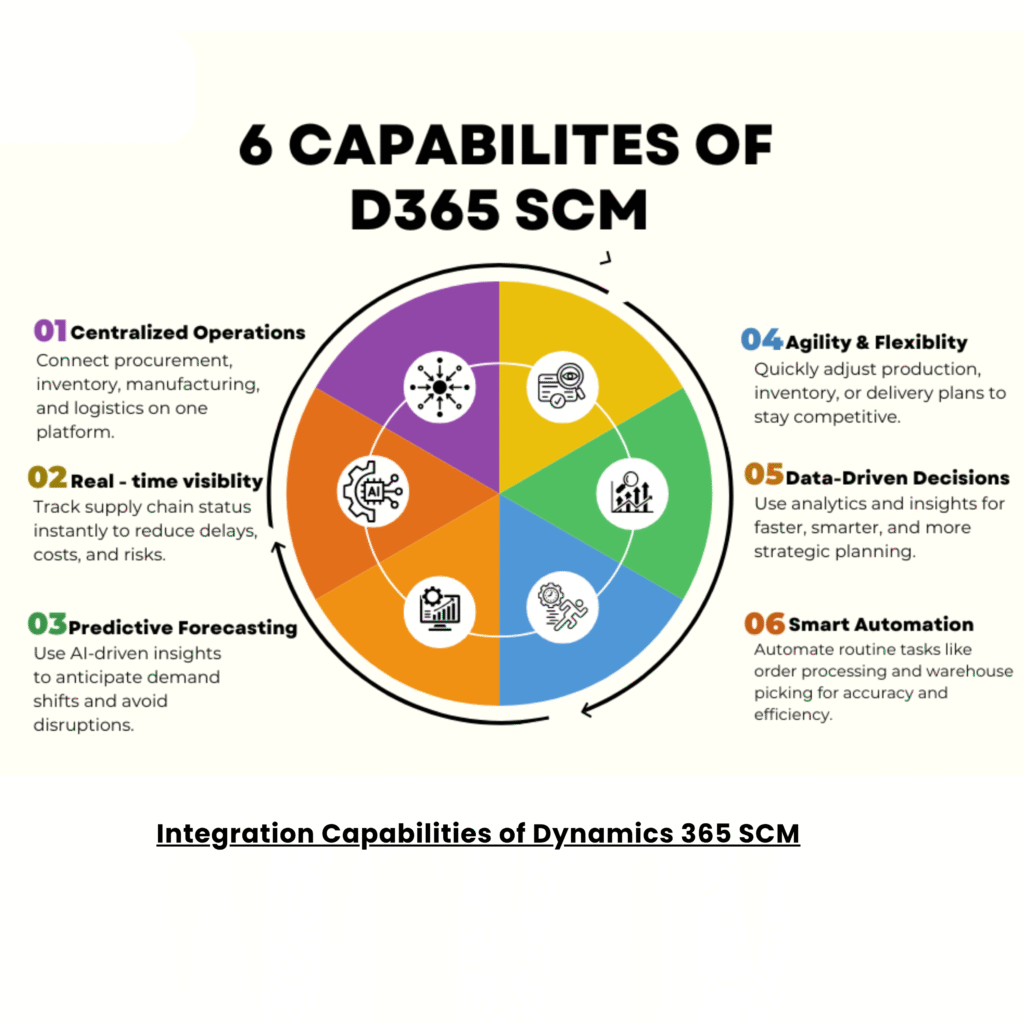

Integration Capabilities of Dynamics 365 SCM

Integration is where Dynamics 365 SCM truly shines. It connects warehouse management with other business applications such as ERP, CRM, and financial systems. This interconnectedness ensures data consistency across the organization and eliminates silos.

When Dynamics 365 SCM integrates with ERP systems, it synchronizes inventory, sales, and financial data. This means that when stock is sold or moved, financial records update automatically. Likewise, connecting it with CRM helps sales teams provide customers with accurate delivery timelines.

The cloud-based architecture of Dynamics 365 enhances flexibility and scalability. Businesses can manage multiple warehouses across regions without needing separate systems. Everything operates under a unified interface accessible from anywhere.

Moreover, the integration capabilities allow companies to connect third-party logistics providers, e-commerce platforms, and IoT devices. Whether you’re using automated robots or smart scanners, Dynamics 365 SCM can integrate seamlessly, ensuring smooth operations from procurement to delivery.

The result is a connected ecosystem where every department has real-time access to accurate information. This not only reduces miscommunication but also drives faster decision-making.

How Dynamics 365 Improves Decision-Making in Warehouse Management

Effective decision-making forms the backbone of every successful warehouse operation. With Dynamics 365 warehouse management, data becomes your most powerful asset. Instead of relying on intuition or outdated reports, managers can use live data dashboards and predictive analytics to make smarter decisions.

One of the key strengths of Dynamics 365 SCM is its ability to provide real-time insights. Every movement, order, or shipment update is captured instantly. These insights help managers identify bottlenecks, measure productivity, and adjust workflows as needed. The system’s built-in analytics tools transform raw data into visual reports, which makes complex information easy to understand.

For instance, if one warehouse section experiences frequent delays, managers can quickly analyze data to determine the cause—whether it’s manpower shortages, machine downtime, or layout inefficiencies. This data-driven clarity allows teams to respond swiftly and strategically.

Beyond operational monitoring, Dynamics 365 SCM incorporates AI-powered forecasting tools. These predictive models anticipate future demand, helping businesses plan purchasing, production, and logistics more efficiently. This eliminates last-minute rushes, minimizes overstocking, and ensures optimal use of warehouse space.

The performance dashboards in Dynamics 365 SCM offer customizable KPIs for different departments. Warehouse supervisors, logistics coordinators, and procurement officers can each access tailored reports suited to their needs. This unified yet flexible visibility ensures that every decision aligns with the company’s broader goals.

Overall, Dynamics 365 SCM converts warehouse management from a reactive process to a proactive strategy. It gives managers the clarity and foresight needed to make confident, data-backed decisions.

Reducing Operational Costs with Dynamics 365 SCM

In the competitive world of supply chain management, reducing operational costs is always a priority. Dynamics 365 warehouse management provides a comprehensive solution that helps organizations cut costs while maintaining quality and efficiency.

One of the primary ways it achieves this is through automation. Automated picking, packing, and restocking processes reduce manual labour requirements and minimize human errors. The system intelligently allocates resources, ensuring that equipment and manpower are used efficiently.

Another cost-saving benefit comes from inventory optimization. With real-time stock tracking in Dynamics 365, businesses can prevent overstocking and understocking issues. Overstocking ties up capital, while understocking leads to missed sales opportunities. Dynamics 365 SCM maintains the perfect balance by predicting demand and adjusting inventory levels accordingly.

Additionally, the integration of logistics operations management reduces unnecessary transportation costs. The platform identifies the most efficient delivery routes and consolidates shipments when possible, saving fuel and time. For companies managing large fleets, these optimizations can translate into substantial cost savings.

Maintenance costs also decrease because the system helps track equipment usage and schedule timely maintenance before breakdowns occur. This predictive maintenance capability extends the lifespan of warehouse assets and prevents costly downtime.

Moreover, by offering a cloud-based solution, Dynamics 365 SCM eliminates the need for expensive on-premise hardware and IT infrastructure. Businesses pay for what they use, allowing flexibility and scalability without hefty upfront investments.

In short, Dynamics 365 SCM improves profitability by reducing costs across labour, inventory, logistics, and maintenance—all while increasing operational efficiency.

Dynamics 365 SCM for Multi-Location Warehousing

Managing multiple warehouses can be complex, but Dynamics 365 warehouse management simplifies it through centralized control and cloud integration. Businesses that operate across different regions or countries can unify all their operations within one platform.

Each warehouse location operates under the same system, enabling consistent workflows, inventory visibility, and standardized processes. When a product moves between locations, Dynamics 365 automatically updates stock records across the entire network. This synchronization prevents double-counting and inventory mismatches.

Additionally, managers can view performance metrics for every warehouse in real time. This helps identify high-performing locations and those that need process improvement. It also supports smarter allocation of resources, ensuring that the right amount of stock is available at the right place.

The cloud-based nature of Dynamics 365 SCM makes it ideal for remote warehouse management. Users can access data from anywhere, collaborate across departments, and make quick decisions without being physically present. This level of control is especially useful for enterprises handling regional or international distribution.

Moreover, by combining multi-location management with logistics operations management, the platform enables seamless inter-warehouse transfers and optimized route planning. This ensures that goods move efficiently between storage centers and customers.

Ultimately, Dynamics 365 SCM brings all warehouse sites under one digital roof, offering clarity, consistency, and complete operational control.

Key Benefits of Implementing Dynamics 365 Warehouse Management

Implementing Dynamics 365 warehouse management delivers multiple tangible benefits that drive operational success. Let’s explore the most impactful advantages businesses experience after adoption:

- End-to-End Visibility

Every aspect of warehouse and inventory management becomes transparent. From incoming shipments to outgoing orders, managers can monitor activities in real time and address issues instantly. - Enhanced Efficiency

Warehouse automation, intelligent stock tracking, and optimized workflows minimize manual errors and speed up operations. This leads to faster order processing and better resource utilization. - Data-Driven Decision Making

Using advanced analytics and AI, Dynamics 365 SCM provides actionable insights. Decision-makers can evaluate performance, forecast trends, and plan ahead with confidence. - Cost Optimization

Automation and intelligent logistics operations management significantly reduce labour, maintenance, and transportation costs. Predictive planning also eliminates financial waste from overstocking. - Scalability and Flexibility

Whether managing one warehouse or hundreds, the cloud-based design ensures smooth scalability. The system grows with the business, accommodating expanding product lines and global operations. - Improved Collaboration

Integration across departments means finance, sales, logistics, and operations share synchronized data. This eliminates silos and fosters seamless communication across the organization. - Customer-Centric Approach

Faster deliveries, accurate tracking, and transparent communication improve customer satisfaction and retention rates.

The overall result is a more intelligent, agile, and efficient supply chain ecosystem that positions companies to meet modern challenges with confidence.

Future of Warehouse and Inventory Management with Dynamics 365 SCM

The future of warehouse management is digital, intelligent, and sustainable—and Dynamics 365 SCM is leading the transformation. As technology evolves, Microsoft continues to integrate cutting-edge tools like artificial intelligence, machine learning, and the Internet of Things (IoT) to make supply chains more adaptive and responsive.

AI and Predictive Analytics are shaping the next generation of warehouse management. Dynamics 365 SCM already uses predictive demand forecasting, but future versions will feature even deeper learning models that can anticipate global supply chain disruptions or seasonal shifts.

Robotics and warehouse automation will also expand. Automated guided vehicles (AGVs) and robotic picking systems will become integral to warehouse operations. Dynamics 365 SCM will serve as the central command hub, orchestrating human-robot collaboration seamlessly.

Sustainability is another emerging focus. Businesses are increasingly prioritizing eco-friendly operations. Dynamics 365 SCM will continue helping companies reduce energy consumption, optimize routes for lower emissions, and manage recyclable packaging materials.

Moreover, enhanced IoT connectivity will further refine stock tracking in Dynamics 365. Sensors embedded in products and containers will relay real-time data on temperature, humidity, and location—ensuring better quality control and traceability.

The future also points toward hyper-personalized customer experiences. With advanced analytics, businesses can anticipate customer needs before they arise, ensuring faster service and tailored delivery options.

In summary, Dynamics 365 SCM is not just keeping pace with digital transformation—it’s defining it. The platform’s continuous innovation ensures that businesses stay agile, efficient, and future-ready in an ever-evolving supply chain landscape.