MD365 SCM 200 Interview Questions and Answers for Experienced in 2025

If you are preparing for Microsoft Dynamics 365 Supply Chain Management (MD 365 SCM) roles in 2025, mastering real interview questions is the best way to succeed. To help professionals, we have compiled 200 MD 365 Supply Chain Management Interview Questions and Answers for Experienced in 2025, based on the latest hiring trends and actual interviews conducted at top MNC companies.

These questions focus on advanced SCM modules like Procurement and Sourcing, Inventory Management, Production Control, Warehouse Management, Demand Forecasting, Transportation Management, and integration with Power BI and Azure services. The answers are structured to give practical explanations that match real-time project scenarios, which is exactly what interviewers expect from experienced candidates.

All these interview questions have been carefully prepared and curated by MyLearnNest Training Institute, a leading provider of MD 365 SCM training in Hyderabad. With strong industry connections, MyLearnNest continuously gathers insights from MNC hiring teams and incorporates them into training and interview preparation material. This ensures that learners not only gain job-ready skills but also have access to the most frequently asked interview questions in today’s job market.

For professionals aiming to advance as SCM Consultants, Functional Analysts, or Solution Architects, these 200 MD 365 SCM interview questions act as the perfect resource to boost confidence and crack interviews with ease.

MD 365 SCM Training in Hyderabad – MyLearnNest Training Academy

MyLearnNest Training Academy provides top-rated MD 365 SCM Training in Hyderabad, crafted to equip learners with practical ERP and supply chain expertise through real-time projects and expert-led guidance. This advanced program covers key modules such as Procurement and Sourcing, Inventory and Warehouse Management, Production Control, Transportation, Demand Forecasting, Master Planning, and Order Management in Microsoft Dynamics 365 Supply Chain Management.

Learners gain hands-on exposure through dedicated ERP labs, live case studies, and industry-driven projects. You will learn how to design, implement, and streamline SCM workflows in Dynamics 365, integrate supply chain processes with finance and sales, and enhance business operations—preparing you for global ERP career opportunities.

This training program is tailored for students, freshers, IT professionals, ERP consultants, and business leaders who wish to upskill in one of the most in-demand Microsoft ERP domains. The curriculum also includes integration with Microsoft Power Platform, BI tools, and Azure cloud deployment, ensuring a complete enterprise-level skill set.

At MyLearnNest, learners benefit from flexible learning modes (online, offline, and self-paced), along with 100% placement support, resume-building sessions, and mock interviews. Upon successful completion, participants receive an industry-recognized MD 365 SCM certification, opening doors to roles such as SCM Consultant, Functional Analyst, ERP Specialist, or Supply Chain Manager.

With lifetime course access, expert faculty, and continuous updates, MyLearnNest ensures you gain job-oriented, practical training and stay competitive in the evolving ERP ecosystem.

MD365 SCM 200 Interview Questions and Answers for Experienced in 2025 Collected from TOP MNCs

- What is the role of the Inventory Management module in Dynamics 365 SCM?

The Inventory Management module in Dynamics 365 SCM helps manage stock levels, track goods across locations, and handle transactions like receipts, issues, and transfers. It supports various inventory valuation methods such as FIFO, LIFO, and Standard Costing. The module ensures accurate real-time stock visibility and integration with production, sales, and procurement. It includes features like warehouse management, product tracking, and quality control. With inventory journals and dimensions, users can adjust and analyze inventory movement. Cycle counting and inventory forecasting improve efficiency. Overall, it optimizes stock levels and reduces carrying costs.

- How does the Master Planning feature work in Dynamics 365 SCM?

Master Planning in Dynamics 365 SCM generates supply and demand plans based on current stock, forecasts, and orders. It helps businesses decide when and how much to procure or produce to meet demand while considering lead times, safety stock, and constraints. The module supports static and dynamic plans, enabling planners to simulate and compare scenarios. Users can configure coverage groups, time fences, and forecast models. It works with intercompany and multisite environments seamlessly. The planning optimization add-in improves performance using Azure. Ultimately, Master Planning streamlines supply chain decision-making and reduces shortages or excess.

- What is the function of Product Information Management in D365 SCM?

Product Information Management (PIM) centralizes product data to ensure consistency across purchasing, sales, and production. It allows users to define product master data, including product dimensions, variants, categories, and attributes. The system supports configuration of released products, bills of materials (BOMs), and product lifecycle states. PIM facilitates multilingual, multisite product definitions, reducing duplication and errors. It also handles version control and change tracking for products. Users can associate documentation and barcodes with items. This module is essential for maintaining accuracy and compliance across the supply chain.

- Can you explain the importance of the Warehouse Management module in D365 SCM?

The Warehouse Management module enhances operational efficiency by enabling advanced storage, tracking, and movement of inventory. It supports inbound and outbound processes like receiving, put-away, picking, packing, and shipping. The module allows warehouse layout setup with zones, locations, and work templates. Mobile device integration provides real-time updates and task execution. Wave and load planning ensure optimized workflows. It also supports cycle counting, replenishment, and labor tracking. With configurable rules and automation, businesses can reduce errors and improve warehouse throughput.

- How does Dynamics 365 SCM handle intercompany trade?

Dynamics 365 SCM simplifies intercompany trade by allowing seamless transactions between related legal entities. It automates the creation of intercompany purchase and sales orders, ensuring consistency in data and inventory movements. Pricing, terms, and delivery can be synchronized across companies. Users can configure intercompany policies and agreements to control transactions. It supports inventory transfers, direct deliveries, and consolidated invoicing. The system helps track financial and operational impact across entities. This reduces manual effort, increases transparency, and ensures regulatory compliance in multi-entity environments.

- What is the significance of the Procurement and Sourcing module in D365 SCM?

The Procurement and Sourcing module helps organizations manage vendor relationships and purchasing activities efficiently. It supports the full procure-to-pay cycle, including vendor onboarding, purchase requisitions, RFQs, purchase orders, and invoicing. Users can define procurement policies, approval workflows, and category hierarchies. It integrates with budgeting and inventory to control costs and ensure timely replenishment. Vendor collaboration portals enhance transparency and communication. The module also supports compliance tracking and performance evaluation. It ensures strategic sourcing, cost optimization, and supply continuity.

- How does D365 SCM support production control and manufacturing operations?

Dynamics 365 SCM offers robust production control features to manage discrete, process, and lean manufacturing. It supports BOMs, routes, production orders, and resource scheduling. Users can track progress, manage materials, and monitor costs throughout the production lifecycle. The system enables real-time visibility into shop floor operations using job cards and terminals. Capacity planning and scheduling tools optimize resource utilization. It integrates with inventory, procurement, and quality modules. These features enhance operational agility, reduce waste, and ensure timely production.

- What are dual-write and its advantages in integrating SCM with Dataverse?

Dual-write is a Microsoft-provided framework that enables near real-time data integration between Dynamics 365 SCM and Microsoft Dataverse (used in Customer Engagement apps). It ensures synchronized data like customers, vendors, products, and orders across ERP and CRM systems. This bi-directional sync eliminates data silos and improves accuracy. It facilitates seamless business processes across front and back office. Dual-write uses standard templates and supports extensibility for custom entities. It reduces integration effort, improves collaboration, and enhances user experience. The unified data model accelerates digital transformation.

- How does D365 SCM handle quality management and compliance?

The Quality Management features in D365 SCM help monitor and enforce product quality across inbound, in-process, and outbound operations. Users can define quality orders, test variables, and sampling plans. Integration with inventory and production ensures timely inspections and quarantining of defective items. Non-conformance tracking and corrective actions help address issues promptly. The system supports regulatory compliance through audit trails and documentation. Quality associations automate checks during transactions. This ensures customer satisfaction, reduces recalls, and maintains industry standards.

- What is the role of costing methods in D365 SCM, and how are they configured?

Costing methods in D365 SCM determine how product costs are calculated and tracked. The system supports FIFO, LIFO, Weighted Average, Standard Cost, and Moving Average methods. Users assign costing versions and cost groups to products based on business needs. The Inventory Valuation process uses these settings to calculate COGS and inventory values. Standard costs require periodic updates through costing sheets and approvals. Actual costing methods track real-time fluctuations. Proper configuration ensures accurate financial reporting and profitability analysis. Integration with finance ensures data consistency and compliance.

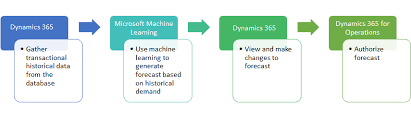

- How is demand forecasting implemented in Dynamics 365 SCM?

Demand forecasting in D365 SCM uses historical data and statistical models to predict future demand. It supports integration with Azure Machine Learning for more accurate, AI-driven forecasts. Users can define forecasting models, select data sources, and adjust predictions manually if needed. Forecasts can be created for products, customers, and regions, supporting multiple time buckets. These forecasts feed into Master Planning to drive procurement and production. The system helps reduce stockouts and excess inventory. Forecast accuracy reports help refine models over time.

- Explain the use of Engineering Change Management (ECM) in D365 SCM.

Engineering Change Management (ECM) enables structured control over product data changes, such as BOMs, routes, and product versions. It introduces engineering versions with effective dates and approvals for better traceability. Change requests and change orders guide the modification process. ECM integrates with Product Lifecycle Management (PLM) tools and maintains compliance records. It provides role-based workflows and document control. This ensures that design changes are accurately reflected in manufacturing and procurement. ECM reduces errors and supports innovation while maintaining control.

- What is the importance of Global Address Book in D365 SCM?

The Global Address Book (GAB) in Dynamics 365 SCM centralizes contact and address information for all entities—customers, vendors, employees, and more. It allows reuse of party data across legal entities, improving consistency and reducing duplication. GAB supports multiple addresses, roles, and contact details for each party. Changes to shared records update across modules automatically. Security roles ensure appropriate access. This centralization improves data quality and administrative efficiency. It’s a foundational element for business partner management in D365.

- How does Dynamics 365 SCM manage inventory reservations?

Inventory reservations in D365 SCM allow businesses to allocate stock to specific orders before actual issue. Users can manually or automatically reserve inventory at the batch, serial, or location level. This ensures product availability for prioritized orders. Reservations can be soft (system-calculated) or hard (user-defined), depending on configuration. They reduce the risk of overcommitting inventory. Integration with sales, production, and transfer orders ensures supply planning accuracy. Effective reservation strategy improves fulfillment rates and customer satisfaction.

- Describe the functionality of Kanban in Lean manufacturing within D365 SCM.

Kanban in Dynamics 365 SCM supports Lean manufacturing by enabling just-in-time production and replenishment. Users define Kanban rules, cards, and flows to automate signal-based material movement. The system tracks demand-driven pull events from production or sales. Kanbans trigger activities like manufacturing, transfer, or purchase. Visual boards display card statuses and help manage workloads. It supports fixed quantity and event-based replenishment. This reduces waste, improves flow, and increases responsiveness on the shop floor.

- What is the use of work templates and location directives in warehouse management?

Work templates and location directives automate warehouse tasks in D365 SCM. Work templates define the sequence and type of operations like picking or putting away. Location directives guide where items should be stored or retrieved based on rules. Together, they optimize warehouse efficiency and accuracy. They support strategies like zone picking, batch picking, and directed put-away. Users can configure filters based on item, location, or quantity. This setup minimizes travel time and ensures space utilization.

- How does D365 SCM manage transportation and shipping operations?

Transportation Management in D365 SCM allows businesses to plan, execute, and monitor shipping activities. Users can define transportation modes, carriers, and rate structures. Load planning consolidates orders into shipments based on capacity and routes. The system supports freight reconciliation, automatic rate shopping, and tendering. Integration with warehouse management ensures timely loading and dispatch. Shipping labels and documents are generated automatically. This functionality reduces logistics costs and improves delivery performance.

- What is the purpose of inventory dimensions in D365 SCM?

Inventory dimensions in D365 SCM provide detailed tracking of products across attributes like site, warehouse, location, batch, and serial number. These dimensions allow for granular control over inventory movements and valuation. Users can configure dimension groups to suit business needs. The system supports physical and financial tracking at each dimension level. This helps in managing shelf life, quality control, and regulatory compliance. Inventory dimensions improve visibility and traceability across the supply chain.

- How does Dynamics 365 SCM support asset management?

Asset Management in D365 SCM helps organizations maintain and track physical assets like machinery and tools. It supports preventive, corrective, and condition-based maintenance plans. Work orders, job types, and resource scheduling streamline operations. The module tracks asset history, costs, warranties, and depreciation. Integration with inventory and procurement ensures spare part availability. IoT sensors can be connected for predictive maintenance. This improves asset reliability, uptime, and reduces operational disruptions.

- Explain the role of costing versions in standard costing within D365 SCM.

Costing versions in D365 SCM allow businesses to manage and simulate standard costs for products. Users can create multiple versions for planning, active use, or what-if analysis. Each version includes BOM and route costs, overheads, and labor rates. Approval workflows ensure proper governance. Once activated, the costing version drives inventory valuation and cost of goods sold. Regular updates and validations help maintain accuracy. This supports strategic pricing and profitability analysis.

- How does Dynamics 365 SCM support catch weight products?

Catch weight products are items sold in variable units like weight or volume but priced by another unit such as pieces. Dynamics 365 SCM supports catch weight by allowing users to define a primary and secondary unit of measure for such items. The system enables tracking and processing in both units throughout procurement, sales, and inventory. It helps manage pricing, invoicing, and costing accurately. Catch weight items often apply to industries like food or chemicals. This functionality ensures compliance and accurate reporting. It also integrates seamlessly with inventory and financial modules.

- What is the role of the Sales and Marketing module in SCM?

Though primarily part of Finance and Operations, the Sales and Marketing module supports SCM by managing sales orders, quotations, and customer interactions. Users can create quotations, convert them into sales orders, and track order fulfillment. Integration with inventory ensures availability checks and accurate delivery dates. It also supports trade agreements, discounts, and commissions. The module helps align supply chain operations with customer demand. It ensures faster response times and better customer service. The tight coupling with warehouse and transportation streamlines order execution.

- How is batch management implemented in D365 SCM?

Batch management in Dynamics 365 SCM enables tracking of inventory by production or receipt batches. Users can configure batch numbers, attributes, and expiration dates. It supports batch reservation, picking, and quality inspection. Batches can be tracked throughout procurement, manufacturing, and sales processes. This is crucial for industries with traceability needs like pharmaceuticals or food. The system supports FEFO (First Expiry First Out) and shelf-life tracking. Batch management improves compliance, quality control, and recall handling.

- What is pegging in Master Planning, and why is it important?

Pegging is a feature in Master Planning that shows the link between demand and the supply that fulfills it. It helps planners understand which sales orders, forecasts, or production demands led to a planned order. Pegging improves decision-making by highlighting dependencies and priorities. Users can trace supply back to the originating demand. This is useful for prioritizing urgent orders or reallocating resources. Pegging enhances transparency and agility in planning. It also helps avoid overproduction or misallocation.

- Describe how inventory journals work in Dynamics 365 SCM.

Inventory journals in D365 SCM are used to make manual inventory adjustments. Common types include movement, transfer, adjustment, and counting journals. Users can correct discrepancies, relocate items, or change inventory statuses. Each journal type supports specific use cases and has its own validation rules. Posting journals updates inventory and financial records. Journals can be batch-processed and integrated with approval workflows. Proper use ensures inventory accuracy and audit compliance.

- How does Dynamics 365 SCM support vendor collaboration?

Vendor collaboration in D365 SCM allows external vendors limited access to the system through a secure portal. Vendors can view and confirm purchase orders, update delivery schedules, and manage invoices. The portal supports communication of product receipts and consignment stock. This improves transparency and reduces email-based coordination. Internal users can control what vendors see and interact with. Collaboration enhances supply chain responsiveness and accuracy. It also builds stronger vendor relationships.

- What are replenishment strategies in warehouse management?

Replenishment strategies in D365 SCM automatically trigger stock movement to maintain inventory levels at picking locations. Strategies include fixed locations, demand-based, or threshold-based replenishment. Users define rules for when and how much to replenish. These settings are linked to wave templates and location directives. The system ensures high availability of fast-moving goods. Replenishment can be triggered manually or during wave processing. Efficient replenishment minimizes downtime and improves order fulfillment rates.

- Explain the role of service management in Dynamics 365 SCM.

Service management supports after-sales service operations such as repairs, installations, and maintenance. Users can create service agreements, orders, and assign technicians. It tracks service history, warranties, and billing. Integration with inventory ensures spare part availability. Time and expense tracking helps calculate service costs. The module supports customer satisfaction by ensuring timely service delivery. It also offers insights into service performance and profitability.

- How does D365 SCM handle returns and return orders?

Returns in Dynamics 365 SCM are managed through return orders, which link back to the original sales or purchase order. Users specify reasons, disposition codes, and expected actions like credit or replacement. The system supports inspection, quarantine, and restocking processes. Integration with inventory and finance ensures accurate valuation and accounting. Returns can trigger quality checks and corrective actions. Automated workflows streamline the approval and processing. This improves customer satisfaction and reduces losses.

- What is the use of trade agreements in procurement and sales?

Trade agreements define pricing, discounts, and conditions for items sold or purchased from vendors and customers. They support quantity breaks, date ranges, and currency-specific rates. Users can create agreements at the item, group, or all-level hierarchy. During transactions, the system automatically applies the best applicable agreement. This simplifies pricing and ensures consistency. Trade agreements are essential for managing negotiated terms. They reduce manual pricing errors and support strategic sourcing.

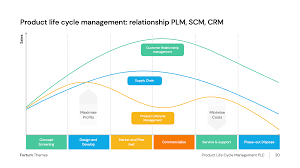

- What is the significance of product lifecycle management (PLM) in Dynamics 365 SCM?

Product Lifecycle Management (PLM) in Dynamics 365 SCM helps manage the entire lifecycle of a product from design to retirement. It integrates with engineering, production, and quality modules to ensure controlled changes and compliance. PLM tracks revisions, approvals, and documentation linked to products. It supports collaboration among different departments, improving transparency and reducing errors. By managing product data centrally, PLM reduces time-to-market and enhances product quality. This system is essential for regulated industries requiring strict control over product changes.

- How does Dynamics 365 SCM facilitate demand-driven replenishment?

Demand-driven replenishment uses actual consumption data and demand signals to trigger restocking activities automatically. In D365 SCM, replenishment rules can be set to reflect real-time sales or production consumption. This approach minimizes stockouts and reduces excess inventory by aligning replenishment closely with true demand. Integration with warehouse and master planning modules ensures timely and efficient stock movements. Alerts and workflows can notify planners about critical levels. Demand-driven methods improve supply chain responsiveness and reduce carrying costs.

- Explain the use of Product Dimensions in inventory management.

Product dimensions categorize inventory items based on attributes like size, color, configuration, or style. In Dynamics 365 SCM, these dimensions allow for detailed tracking and segregation of inventory for sales and production. Dimensions help control inventory valuation, picking strategies, and reporting. Configuring product dimension groups ensures consistency across transactions. This granular tracking supports complex product portfolios and customer preferences. It also aids in accurate forecasting and planning by understanding demand variations by dimension.

- What are the different types of warehouse layouts supported in D365 SCM?

D365 SCM supports flexible warehouse layouts including zones, aisles, racks, shelves, and bins. Users can design warehouses to reflect physical structures accurately. This supports directed put-away and picking strategies by mapping item locations precisely. The system allows configuration of storage policies based on item attributes or demand. Multiple warehouses and locations can be managed across legal entities. This flexibility improves space utilization and operational efficiency. Accurate layouts support advanced warehouse tasks like wave picking and replenishment.

- How does Advanced Warehouse Management improve operational efficiency?

Advanced Warehouse Management (WMS) in D365 SCM provides automation and control over complex warehouse processes. It supports mobile device integration, task interleaving, and real-time inventory visibility. Features include wave management, load planning, quality control, and labor tracking. The system automates put-away, picking, and replenishment with rules-based workflows. It enhances accuracy through barcode scanning and RFID support. This leads to faster throughput, reduced errors, and optimized labor costs. Advanced WMS supports scalability for growing warehouse operations.

- Describe the use of inventory closing in Dynamics 365 SCM.

Inventory closing in D365 SCM is a periodic process to reconcile physical inventory with financial records. It adjusts inventory valuations, costs, and ledger postings to ensure accuracy. During closing, costing versions are finalized, and variance calculations are posted. The process helps in maintaining consistent cost accounting and profitability analysis. Users can run trial closings to validate data before final posting. Inventory closing supports audit requirements and financial reporting standards. Proper execution reduces discrepancies between operational and financial data.

- What is the difference between cycle counting and physical inventory in D365 SCM?

Cycle counting is an ongoing, scheduled inventory audit of specific items or locations to maintain accuracy. It allows for incremental counts without shutting down operations. Physical inventory is a full inventory count usually conducted periodically, requiring system downtime or special procedures. D365 SCM supports both methods with dedicated journals and workflows. Cycle counting helps identify issues early and reduces discrepancies. Physical inventory ensures comprehensive validation. Both methods integrate with inventory adjustment processes for reconciliation.

- How does D365 SCM manage production orders and their lifecycle?

Production orders in D365 SCM represent manufacturing jobs with defined BOMs, routes, and schedules. The lifecycle starts with creation, approval, and scheduling, followed by material picking and execution. Users can track order status, progress, and costs in real-time. The system supports partial reporting, scrap handling, and rework. After completion, production orders trigger inventory and financial updates. Integration with quality management ensures inspection during production. This lifecycle management helps optimize production efficiency and cost control.

- Explain how service items are managed in Dynamics 365 SCM.

Service items refer to products tracked for service management such as warranties or repairs. In D365 SCM, these items have unique tracking, including serial numbers or warranties. The system links service orders to inventory and asset management modules for spare parts and maintenance history. Service items can trigger automatic alerts for preventive maintenance. Tracking service items ensures accountability and customer satisfaction. It supports cost allocation and profitability analysis of service operations. Integration with CRM enhances service lifecycle visibility.

- What is the purpose of product receipts and product returns in D365 SCM?

Product receipts record the receipt of goods into inventory from purchase orders, ensuring quantity and quality verification. They update inventory and financial accounts, reflecting the incoming stock. Product returns handle the process of returning defective or unwanted goods to vendors. The system tracks return reasons, manages inspection, and updates inventory accordingly. Integration with vendor collaboration streamlines return authorizations. Proper management of receipts and returns maintains inventory accuracy and supplier relationships. It also supports compliance and audit requirements.

- How does Dynamics 365 SCM integrate with Power BI for reporting and analytics?

Dynamics 365 SCM integrates seamlessly with Power BI, enabling users to create rich, interactive dashboards and reports using real-time data from the SCM system. This integration allows business users and managers to monitor key performance indicators such as inventory levels, order fulfillment, and supplier performance. Power BI offers customizable visualizations and drill-down capabilities for deep analysis. Data models can be refreshed automatically, ensuring up-to-date insights. Users can combine SCM data with other enterprise data sources for comprehensive analytics. This empowers data-driven decision-making across supply chain functions.

- What are the different types of master data maintained in D365 SCM?

Master data in Dynamics 365 SCM includes key foundational information such as products, vendors, customers, units of measure, warehouses, and cost groups. Product master data covers item details, categories, dimensions, and BOMs. Vendor and customer master data manage business partner information, including addresses and payment terms. Units of measure define how quantities are managed and converted. Warehouses and locations detail physical storage layouts. Accurate master data is essential for transaction processing and reporting. Maintaining clean and consistent master data ensures system reliability and operational efficiency.

- How does the system support multi-site and multi-warehouse operations?

Dynamics 365 SCM supports organizations with multiple physical locations and warehouses. Users can configure multiple legal entities, sites, and warehouses, each with distinct inventory, costing, and operational rules. The system enables stock transfers between sites and warehouses with full tracking. Multi-site management supports centralized or decentralized procurement and production. Users can apply location-specific policies for replenishment, picking, and storage. This flexibility accommodates complex supply chains and global operations. Integration with financial modules ensures accurate intercompany accounting.

- What is the purpose of product variants in Dynamics 365 SCM?

Product variants allow businesses to manage multiple versions of a product that differ in attributes such as size, color, or style. In D365 SCM, variants enable efficient product setup without creating separate items for each variation. Users define variant configurations linked to a base product. This supports streamlined order entry, inventory tracking, and production. Variants improve customer choice management and reduce data maintenance. The system manages pricing, inventory, and reporting at the variant level. This functionality enhances product catalog flexibility and sales effectiveness.

- Explain how shelf life management works in Dynamics 365 SCM.

Shelf life management tracks the usable life of perishable products and helps prevent spoilage or obsolescence. Users can define shelf life periods and expiration dates for batch or serial-controlled items. The system supports automatic notifications for items approaching expiry. Shelf life status affects inventory availability and valuation. Picking and replenishment strategies consider shelf life to prioritize older stock. This management is crucial for industries like pharmaceuticals and food. It reduces waste, ensures compliance, and improves product quality management.

- How does Dynamics 365 SCM handle intercompany transactions?

Intercompany transactions facilitate business activities between legal entities within the same organization. D365 SCM supports automatic creation of corresponding purchase and sales orders, invoices, and shipments between entities. The system manages intercompany pricing, taxes, and currency conversion. Users can track and reconcile intercompany balances. Integration with general ledger ensures accurate financial reporting. Workflow automation improves process efficiency and reduces manual errors. Intercompany features support consolidated reporting and compliance with accounting standards.

- What are the benefits of using alerts and workflows in D365 SCM?

Alerts and workflows automate notifications and approvals to streamline business processes in Dynamics 365 SCM. Alerts notify users about critical events such as low inventory, delayed shipments, or quality issues. Workflows enforce business rules and approval hierarchies, reducing errors and ensuring compliance. They improve communication across teams by routing tasks and escalations automatically. Customizable alerts and workflows adapt to organizational needs. This automation enhances operational efficiency and responsiveness. It also supports audit trails and accountability.

- Describe the process of creating a transfer order in warehouse management.

A transfer order in D365 SCM initiates the movement of inventory between warehouses or locations. The process starts with creating a transfer order specifying the source and destination. The system checks inventory availability and generates work tasks for picking, packing, and shipping. Warehouse workers execute these tasks using mobile devices or terminals. Upon receipt at the destination, the order is confirmed, updating inventory and financial records. Transfer orders support inter-warehouse replenishment and balancing. This process ensures traceability and efficient stock management across locations.

- How does the system ensure data security and compliance in SCM?

Dynamics 365 SCM employs role-based security to control access to data and functionality. Users are assigned roles that define permissions based on job responsibilities. The system supports segregation of duties to prevent conflicts of interest. Data encryption protects sensitive information in transit and at rest. Audit trails capture changes to critical data for compliance and investigation. Integration with Microsoft’s security framework ensures regular updates and threat protection. Compliance with standards like GDPR and SOX is supported through configurable policies. This ensures secure and compliant operations across the supply chain.

- What is the significance of the Product Information Management (PIM) module?

The Product Information Management (PIM) module centralizes product data, including attributes, categories, and documents. It ensures consistent and accurate product definitions across the enterprise. PIM supports complex product configurations and variant management. Users can manage product hierarchies and relationships, improving catalog management. Integration with other modules like procurement, sales, and inventory ensures data synchronization. PIM facilitates better decision-making by providing a single source of truth. It reduces data redundancy and improves operational efficiency.

- How does Dynamics 365 SCM handle quality management during production?

Quality management in Dynamics 365 SCM is tightly integrated with production processes to ensure product compliance and standards. The system allows users to define quality tests and inspection plans linked to production orders and batches. Inspections can be triggered automatically at various production stages, including raw material receipt and final output. Results are recorded and deviations managed through non-conformance reports. This integration helps detect defects early, reduce scrap, and maintain high-quality standards. Quality data also supports regulatory compliance and continuous improvement initiatives.

- What is the role of demand forecasting in Dynamics 365 SCM?

Demand forecasting in D365 SCM uses historical sales data, market trends, and seasonal patterns to predict future product demand. It helps businesses plan procurement, production, and inventory levels more accurately. The system supports different forecasting models like moving average and regression analysis. Forecasts feed directly into master planning, enabling proactive supply chain decisions. Accurate forecasting reduces stockouts and excess inventory, improving customer satisfaction and cash flow. Continuous adjustment based on real-time data refines forecast accuracy over time.

- Explain how transportation management integrates with SCM in Dynamics 365.

Transportation management in Dynamics 365 SCM optimizes the planning and execution of inbound and outbound shipments. It supports carrier selection, route optimization, and freight cost calculation. Integration with warehouse management ensures timely loading and unloading aligned with shipment schedules. The system tracks shipment status and provides real-time visibility. It facilitates compliance with shipping regulations and documentation requirements. Transportation management enhances delivery performance and cost control by automating manual tasks and improving coordination across supply chain functions.

- How does D365 SCM support serial number tracking?

Serial number tracking assigns unique identifiers to individual items for precise tracking throughout the supply chain. In D365 SCM, serial numbers can be assigned at receipt, production, or sales. The system records serial number movements, enabling traceability for warranty, recalls, and service management. Serial tracking supports inventory accuracy, theft prevention, and quality control. It also facilitates compliance with industry regulations requiring item-level tracking. Integration with sales and service modules helps manage product lifecycle and customer support effectively.

- What is a license plate in warehouse management, and how is it used?

A license plate in warehouse management is a unique identifier assigned to a pallet or container holding multiple items. It simplifies inventory tracking by managing stock at the container level rather than individual items. License plates enable quicker put-away, picking, and shipment processes by scanning a single code. They support handling unit management and improve accuracy in complex warehouse operations. The system allows nested license plates for multi-level packaging. License plate management enhances operational efficiency and reduces errors.

- Describe the process of wave management in Dynamics 365 SCM.

Wave management groups warehouse work into batches called waves for efficient processing. In D365 SCM, waves are created based on criteria like order priority, shipping deadlines, or product types. The system generates work tasks for picking, packing, and shipping within each wave. Waves help optimize resource allocation and reduce operational bottlenecks. Managers can monitor wave progress and adjust workloads in real-time. Integration with transportation and production scheduling ensures coordinated order fulfillment. Wave management enhances throughput and customer service.

- How are consignment stocks managed in Dynamics 365 SCM?

Consignment stock refers to inventory owned by a vendor but stored on the buyer’s premises. Dynamics 365 SCM allows tracking of consignment stock separately from owned inventory. The system supports processes for receiving, issuing, and returning consignment items. Financial ownership remains with the vendor until the stock is consumed or sold. Users can generate reports to monitor consignment usage and reconcile balances. This functionality improves inventory transparency and supplier collaboration. It reduces working capital tied up in inventory while ensuring availability.

- What is the importance of the Product Receipt journal in procurement?

The Product Receipt journal records the receipt of goods against purchase orders, confirming delivery quantities and quality. In Dynamics 365 SCM, posting product receipts updates inventory and triggers financial postings to accounts payable. It is crucial for accurate inventory valuation and supplier payment processing. The system supports partial receipts and backorders management. Product receipt data also integrates with quality inspection workflows. Timely and accurate product receipt handling ensures inventory accuracy and smooth procurement operations.

- How does Dynamics 365 SCM facilitate cross-docking in warehouses?

Cross-docking is a logistics practice where incoming goods are directly transferred to outbound shipments with minimal storage. D365 SCM supports cross-docking by enabling warehouse processes that route goods quickly through receiving to shipping docks. The system manages inbound and outbound orders to synchronize timings and quantities. Cross-docking reduces handling costs, storage needs, and delivery lead times. It is especially useful for high-turnover or perishable items. Automated workflows and task management ensure efficient execution of cross-docking operations.

- Explain the concept of inventory reservation in Dynamics 365 SCM.

Inventory reservation locks stock for specific sales or production orders to guarantee availability. In Dynamics 365 SCM, reservation can be manual or automatic during order entry or master planning. It ensures that allocated inventory isn’t used for other orders, preventing stock conflicts. Reservations update availability calculations in real-time and integrate with warehouse workflows. The system supports partial and full reservations and can release stock if orders are canceled. Effective reservation management improves order fulfillment reliability and customer satisfaction.

- What is the significance of the Inventory Close process in Dynamics 365 SCM?

The Inventory Close process in Dynamics 365 SCM is critical for ensuring that inventory transactions and financial postings are reconciled for a specific period. It finalizes costing versions, updates inventory valuations, and posts inventory adjustments to the general ledger. This process helps in maintaining accurate inventory balances and cost information. Inventory Close supports audit compliance and financial reporting accuracy. Businesses typically run inventory closes monthly or quarterly to align operational and financial data. It also helps identify discrepancies and correct them timely.

- How does Dynamics 365 SCM support batch number tracking?

Batch number tracking allows businesses to assign and monitor production or procurement batches for items requiring traceability. In Dynamics 365 SCM, batches can include expiration dates, quality test results, and supplier details. The system tracks batch movements through warehouses, production, and sales. This functionality is essential for industries such as pharmaceuticals and food where batch integrity and recall capability are critical. Batch tracking supports compliance, quality assurance, and accurate reporting. Users can perform batch reservations and traceability analysis easily.

- Explain the use of Replenishment Policies in D365 SCM.

Replenishment policies in Dynamics 365 SCM automate inventory restocking based on predefined criteria such as minimum stock levels, lead times, and demand forecasts. These policies determine when and how much to order or produce, optimizing inventory levels and preventing stockouts. The system supports various replenishment methods like Kanban, Min/Max, and reorder point. Integration with master planning and procurement ensures timely generation of purchase or production orders. Replenishment policies help balance service levels with inventory carrying costs, improving supply chain efficiency.

- How are landed costs managed in Dynamics 365 SCM?

Landed costs are the total costs associated with purchasing goods, including freight, customs duties, insurance, and other fees. Dynamics 365 SCM supports landed cost calculation and allocation to inventory. The system enables users to define cost components and allocate them based on quantity, weight, or value. Landed costs are added to the item cost, improving cost accuracy and profitability analysis. This functionality supports compliance with accounting standards and improves financial reporting. Landed cost management helps in better pricing and inventory valuation decisions.

- What is the role of the Procurement category hierarchy in D365 SCM?

The Procurement category hierarchy organizes goods and services into categories for better spend analysis and procurement management. In Dynamics 365 SCM, categories can be structured in multiple levels to reflect business needs. This hierarchy supports vendor selection, contract management, and budget control. It enables better reporting on procurement activities and helps identify cost-saving opportunities. The system uses categories for purchase requisitions, orders, and approvals. Effective category management enhances procurement efficiency and strategic sourcing.

- Describe the concept of ‘whitelisting’ in D365 SCM security.

Whitelisting in Dynamics 365 SCM security restricts system access to approved IP addresses, devices, or users. It acts as a layer of protection by allowing only trusted entities to connect to the system. This reduces the risk of unauthorized access and cyber threats. Whitelisting complements role-based access controls and encryption. Organizations use whitelisting to comply with regulatory requirements and safeguard sensitive supply chain data. It is typically managed by IT administrators and regularly reviewed to maintain security integrity.

- How does D365 SCM handle production scheduling?

Production scheduling in Dynamics 365 SCM coordinates manufacturing orders with available resources and capacity. The system considers factors like work center availability, tool requirements, and material readiness. It supports finite and infinite scheduling methods, allowing planners to optimize production sequences and timelines. Integration with master planning and inventory ensures that materials and labor are available as scheduled. The scheduling engine can reschedule orders dynamically in response to changes or delays. Effective scheduling improves throughput, reduces downtime, and meets customer delivery commitments.

- What is the use of the ‘work template’ in warehouse management?

A work template in Dynamics 365 SCM defines a sequence of warehouse tasks, such as picking, packing, and put-away. It standardizes repetitive warehouse processes, ensuring consistency and efficiency. Work templates can be customized based on item types, locations, or order priorities. The system automatically generates tasks according to the template when warehouse work is created. This reduces manual intervention and errors, improving productivity. Work templates also support complex processes like cross-docking and wave picking.

- Explain the difference between a production BOM and a sales BOM.

A production BOM (Bill of Materials) details the components and quantities required to manufacture a finished product. It is used in the production process to plan and consume materials. A sales BOM represents a product kit sold as a single unit but stocked and managed as separate components. Sales BOMs are used primarily for order fulfillment and inventory management. In Dynamics 365 SCM, both BOM types support different business processes but can be linked for integrated planning. Understanding this distinction helps optimize production and sales operations.

- How is environmental sustainability addressed in Dynamics 365 SCM?

Dynamics 365 SCM supports environmental sustainability by enabling efficient resource utilization and waste reduction throughout the supply chain. Features like optimized routing, demand forecasting, and inventory management reduce energy consumption and emissions. The system can track compliance with environmental regulations and sustainability standards. Integration with IoT and sensors helps monitor environmental conditions in warehouses and production. Sustainable procurement and product lifecycle management modules assist companies in minimizing environmental impact. These capabilities help businesses meet corporate social responsibility goals.

- How does Dynamics 365 SCM manage vendor collaboration?

Dynamics 365 SCM facilitates vendor collaboration through integrated portals and communication tools that allow vendors to access purchase orders, delivery schedules, and invoice status. This transparency improves order accuracy and lead times. The system supports electronic data interchange (EDI) for seamless information exchange. Vendors can update shipment tracking and confirm deliveries directly in the system. Enhanced collaboration reduces errors, speeds up procurement cycles, and strengthens supplier relationships. This integration ensures better alignment between buyers and suppliers.

- What is the function of ‘cycle counting’ in warehouse management?

Cycle counting in Dynamics 365 SCM is an inventory audit technique where a subset of inventory is counted on a rotating schedule, rather than a full physical inventory. This method helps maintain continuous accuracy in inventory records without disrupting daily operations. The system allows users to define counting frequencies based on item value, movement, or other criteria. Cycle counting helps identify discrepancies early, reduce shrinkage, and improve inventory reliability. It also supports compliance and operational efficiency by minimizing downtime for audits.

- Explain the importance of ‘configuration management’ in product lifecycle.

Configuration management in Dynamics 365 SCM ensures that product data, including specifications, versions, and options, is accurately maintained throughout the product lifecycle. This control is essential when products have complex variants or customizations. The system tracks changes, approvals, and releases of configurations to prevent errors and ensure consistency. Proper configuration management supports engineering, manufacturing, and service processes by providing a reliable source of product information. It enhances product quality and reduces rework and costs.

- How does Dynamics 365 SCM support compliance with trade regulations?

Dynamics 365 SCM supports compliance with international trade regulations by managing customs documentation, tariffs, import/export controls, and trade agreements. The system can automate classification of goods, calculate duties, and generate required regulatory reports. Integration with global trade services ensures up-to-date regulation enforcement. Automated workflows help reduce risks of penalties and delays at borders. The solution aids businesses in managing complex cross-border logistics while ensuring legal compliance and minimizing supply chain disruptions.

- Describe how quality order management is handled in D365 SCM.

Quality order management in Dynamics 365 SCM is a structured process that triggers quality inspections and testing based on defined criteria. When a quality order is created, tasks are assigned to quality personnel for execution of tests on products or materials. Inspection results are documented, and any deviations are managed through corrective actions or non-conformance reports. The system tracks status and history of quality orders to maintain traceability. Integration with production and warehouse modules ensures only compliant products proceed through the supply chain, safeguarding customer satisfaction and compliance.

- What are the different types of inventory models supported in Dynamics 365 SCM?

Dynamics 365 SCM supports several inventory models including periodic, perpetual, and consignment. The perpetual inventory model continuously updates inventory balances with each transaction, providing real-time accuracy. The periodic model updates inventory at specific intervals through physical counts. Consignment inventory is tracked separately but stored at the buyer’s location with ownership remaining with the vendor. The system supports FIFO, LIFO, weighted average, and standard costing methods for inventory valuation. This flexibility allows organizations to select models aligning with their operational and financial requirements.

- How does Dynamics 365 SCM improve warehouse picking efficiency?

Dynamics 365 SCM improves warehouse picking efficiency by utilizing advanced techniques like wave picking, zone picking, and batch picking. It generates optimized picking routes based on warehouse layout and order priority to minimize travel time. Integration with mobile devices and barcode scanners reduces errors and speeds up task completion. Real-time updates allow supervisors to monitor progress and reassign resources dynamically. Automation through work templates and task interleaving further enhances throughput. These capabilities reduce labor costs and improve order fulfillment accuracy.

- Explain the role of demand-driven replenishment in Dynamics 365 SCM.

Demand-driven replenishment in Dynamics 365 SCM aligns inventory replenishment with actual consumption patterns and customer demand signals. Instead of relying solely on forecasts, the system dynamically adjusts orders based on real-time sales and stock levels. This reduces excess inventory and stockouts by responding quickly to market changes. Demand-driven replenishment supports lean inventory principles and enhances supply chain agility. It integrates with master planning and vendor collaboration modules to synchronize supply and demand. Overall, it improves service levels while lowering inventory carrying costs.

- What are the key features of Dynamics 365 SCM’s warehouse mobile app?

The warehouse mobile app in Dynamics 365 SCM provides warehouse workers with real-time access to tasks such as picking, receiving, and inventory counting. It supports barcode scanning, voice commands, and offline operation to maintain productivity in diverse environments. The app integrates seamlessly with the warehouse management system, updating inventory and work statuses instantly. It enhances accuracy by reducing manual data entry and errors. The intuitive interface simplifies complex processes, enabling faster onboarding of staff. This mobility improves operational efficiency and responsiveness.

- How does Dynamics 365 SCM handle product recalls?

Product recalls in Dynamics 365 SCM are managed through batch and serial number traceability that allows identification of affected products quickly. When a recall is initiated, the system can generate reports detailing locations and customers impacted by the issue. Recall workflows facilitate communication with stakeholders, manage returns, and ensure proper disposal or rework of recalled items. Integration with quality management ensures root cause analysis and preventive actions. Effective recall management protects brand reputation, complies with regulations, and minimizes financial and operational impacts.

- What is the significance of master planning in Dynamics 365 SCM?

Master planning in Dynamics 365 SCM is a critical function that helps synchronize supply and demand by generating production and purchase orders based on forecasted demand, inventory levels, and open sales orders. It considers lead times, capacity constraints, and inventory policies to optimize planning and avoid stockouts or overstock situations. The process enables businesses to balance operational efficiency with customer service levels. Master planning supports both materials requirement planning (MRP) and distribution requirements planning (DRP), making supply chain execution more predictable and cost-effective.

- How does Dynamics 365 SCM facilitate inventory aging analysis?

Inventory aging analysis in Dynamics 365 SCM helps organizations identify slow-moving or obsolete stock by categorizing inventory based on the length of time items have been in stock. The system generates reports that segment inventory into aging buckets, providing insights into inventory turnover and potential write-offs. This analysis supports better decision-making around promotions, discounts, or disposal. Aging data can also inform replenishment strategies to optimize working capital. Monitoring inventory aging reduces holding costs and improves overall inventory health.

- Explain the use of ‘safety stock’ in Dynamics 365 SCM.

Safety stock in Dynamics 365 SCM acts as a buffer inventory to protect against uncertainties in demand and supply, such as delays or demand spikes. The system allows setting safety stock levels based on historical variability, lead times, and service level targets. Safety stock ensures that customer orders can be fulfilled even during disruptions, reducing the risk of stockouts. It is incorporated into master planning calculations to trigger replenishment orders proactively. Proper safety stock management balances inventory carrying costs with service reliability.

- What is a ‘work template’ and how does it enhance warehouse processes?

A work template in Dynamics 365 SCM is a predefined sequence of tasks that standardizes warehouse operations such as picking, packing, and put-away. It ensures that complex workflows are executed consistently and efficiently by automating task creation based on item types or order characteristics. Work templates reduce manual errors and improve labor productivity by guiding warehouse workers step-by-step. They also support various fulfillment strategies like wave picking and cross-docking. By streamlining operations, work templates help warehouses achieve faster throughput and better accuracy.

- How is the Vendor Collaboration Portal used in Dynamics 365 SCM?

The Vendor Collaboration Portal in Dynamics 365 SCM enables suppliers to interact directly with the purchasing organization, accessing purchase orders, invoices, shipment details, and payment status. This self-service portal improves communication, reduces administrative overhead, and accelerates transaction cycles. Vendors can update shipment tracking, confirm deliveries, and submit invoices electronically. The portal enhances transparency and helps resolve issues quickly. By fostering closer collaboration, it supports supply chain agility and strengthens supplier relationships.

- Describe how batch picking differs from wave picking in Dynamics 365 SCM.

Batch picking involves picking multiple orders simultaneously by grouping similar items together to improve picking efficiency, especially for high-volume products. Wave picking, on the other hand, organizes picking into waves based on criteria like shipping deadlines or customer priorities, coordinating multiple orders for processing as a batch. While batch picking focuses on item similarity, wave picking is more about timing and workflow optimization. Both methods reduce travel time and improve resource utilization in warehouses, but they serve different operational needs and can be combined for complex fulfillment strategies.

- How does Dynamics 365 SCM manage inventory discrepancies?

Inventory discrepancies occur when physical stock levels differ from system records. Dynamics 365 SCM provides tools for investigating discrepancies through cycle counting and physical inventory processes. The system allows users to adjust inventory levels with appropriate financial postings and trace discrepancies back to transactions or processes. Reporting and audit trails help identify root causes such as theft, damage, or data entry errors. Resolving discrepancies promptly maintains inventory accuracy, supports financial integrity, and improves supply chain reliability.

- What is the function of the ‘product receipt’ process in procurement?

The product receipt process in Dynamics 365 SCM confirms the physical receipt of goods against purchase orders. It updates inventory quantities and triggers financial postings to accounts payable, ensuring accurate stock valuation and supplier payment. The process supports partial and backorder receipts, facilitating flexible handling of deliveries. Integration with quality management allows inspection of received goods before acceptance. Proper product receipt processing is essential for maintaining inventory accuracy and controlling procurement costs.

- How is role-based security implemented in Dynamics 365 SCM?

Role-based security in Dynamics 365 SCM restricts user access based on job roles and responsibilities. Administrators assign security roles that define permissions to data, forms, and actions within the system. This approach ensures users see only the information necessary for their tasks, enhancing data security and compliance. Roles can be customized and combined to meet organizational requirements. Role-based security reduces risks of unauthorized access and errors by limiting system functions according to defined policies.

- Explain how production orders are managed in Dynamics 365 SCM.

Production orders in Dynamics 365 SCM manage the manufacturing process from start to finish. They contain details about the product to be produced, required components, routing, and operations. The system tracks production progress, resource usage, and costs, providing real-time visibility. Production orders integrate with inventory, quality, and warehouse modules to ensure materials availability and compliance. Completion of a production order updates inventory with finished goods and consumes raw materials. This structured management improves manufacturing efficiency and product traceability.

- What is the difference between ‘Push’ and ‘Pull’ replenishment methods in Dynamics 365 SCM?

In Dynamics 365 SCM, the ‘Push’ replenishment method involves planning and releasing production or purchase orders based on forecasts or planned demand, pushing inventory through the supply chain proactively. Conversely, the ‘Pull’ method triggers replenishment based on actual consumption or customer demand signals, pulling inventory as needed to fulfill orders. Push is useful for long lead times and predictable demand, while Pull supports lean inventory and just-in-time principles. The system supports both methods to accommodate diverse business requirements and improve responsiveness.

- How does Dynamics 365 SCM integrate with Power BI for supply chain analytics?

Dynamics 365 SCM integrates seamlessly with Power BI to provide advanced data visualization and analytics capabilities. Users can create interactive dashboards and reports combining operational data from SCM with financial and customer insights. This integration enables real-time monitoring of key performance indicators (KPIs) such as inventory turnover, order fulfillment rates, and supplier performance. Power BI’s drag-and-drop interface allows business users to explore data without technical expertise. The combined solution empowers data-driven decision-making and continuous supply chain improvement.

- Explain how Dynamics 365 SCM handles returns management.

Returns management in Dynamics 365 SCM facilitates the processing of returned goods from customers or vendors efficiently. The system supports authorization workflows, inspection upon receipt, and disposition decisions such as restocking, repair, or disposal. Returns are linked to original orders for traceability and financial reconciliation. Integration with quality management ensures returned items meet company policies. Automated processes reduce manual effort, improve customer satisfaction, and help recover value from returned inventory.

- What is the role of ‘item coverage’ in master planning?

Item coverage in Dynamics 365 SCM defines the rules and parameters that determine how inventory replenishment is managed for specific items. It includes settings like minimum and maximum stock levels, lead times, and coverage groups. Master planning uses item coverage data to generate procurement or production proposals that maintain optimal inventory levels. By customizing coverage settings per item, businesses can prioritize critical stock and reduce excess inventory. This granular control helps improve inventory turnover and service levels.

- How is warehouse slotting managed in Dynamics 365 SCM?

Warehouse slotting in Dynamics 365 SCM optimizes the placement of inventory items within the warehouse to improve picking efficiency and space utilization. The system analyzes product attributes, movement frequency, and storage requirements to suggest optimal locations. Slotting can be dynamic, adjusting locations based on changing demand patterns. Proper slotting reduces travel time for warehouse staff and accelerates order fulfillment. Integration with warehouse management workflows ensures that slotting recommendations are implemented effectively.

- Describe the use of ‘consignment inventory’ in Dynamics 365 SCM.

Consignment inventory in Dynamics 365 SCM refers to stock owned by a supplier but stored at the buyer’s location until it is used or sold. This arrangement reduces the buyer’s working capital investment since payment is made only when inventory is consumed. The system tracks consignment stock separately, enabling accurate reporting and billing. It supports replenishment and returns processes specific to consignment agreements. Managing consignment inventory effectively improves cash flow and supplier collaboration.

- How does Dynamics 365 SCM support multi-site warehouse management?

Dynamics 365 SCM supports multi-site warehouse management by enabling organizations to manage inventory and operations across multiple physical locations. The system tracks stock quantities, movements, and orders by site, allowing centralized or decentralized control. Inter-site transfers and replenishment processes are streamlined to maintain optimal stock levels across locations. Reporting and analytics provide visibility into each site’s performance. Multi-site capabilities help businesses scale operations and optimize inventory distribution geographically.

- What are the benefits of using Electronic Data Interchange (EDI) in Dynamics 365 SCM?

EDI integration in Dynamics 365 SCM automates the exchange of business documents such as purchase orders, invoices, and shipping notices between trading partners. This reduces manual data entry, errors, and processing times. EDI supports faster transaction cycles and improves accuracy in procurement and sales processes. The system can handle various EDI standards and protocols, enabling global supply chain connectivity. Using EDI enhances supplier collaboration and strengthens supply chain efficiency.

- Explain the process of ‘production scheduling’ in Dynamics 365 SCM.

Production scheduling in Dynamics 365 SCM involves planning and sequencing manufacturing operations to optimize resource utilization and meet delivery deadlines. The system considers constraints such as work center capacity, tooling availability, and material readiness. It supports finite and infinite scheduling methods, allowing flexibility in managing workloads. Real-time updates and rescheduling capabilities enable quick responses to disruptions or priority changes. Effective production scheduling improves throughput, reduces lead times, and ensures timely order fulfillment.

- How does Dynamics 365 SCM facilitate compliance with industry standards?

Dynamics 365 SCM helps organizations comply with industry standards by providing robust quality management, traceability, and audit trail capabilities. The system supports documentation and workflows required by standards such as ISO, FDA, and GMP. Features like batch and serial tracking, quality orders, and inspection management ensure product integrity and safety. Automated reporting and alerts assist in regulatory audits and continuous improvement initiatives. By embedding compliance into core processes, D365 SCM reduces risk and enhances operational excellence.

- What is the purpose of the ‘Demand Forecasting’ feature in Dynamics 365 SCM?

Demand Forecasting in Dynamics 365 SCM uses historical sales data and statistical models to predict future product demand. This helps businesses plan procurement, production, and inventory more accurately, minimizing stockouts and excess inventory. Forecasts can be adjusted manually based on market trends or promotions. The feature supports various algorithms and can be integrated with master planning for synchronized supply chain operations. Accurate forecasting improves customer satisfaction and reduces carrying costs.

- How does Dynamics 365 SCM handle serialization and traceability?

Serialization in Dynamics 365 SCM assigns unique serial numbers to individual products, enabling precise tracking throughout the supply chain. This ensures full traceability from production through sales and service. Serialization supports warranty management, recalls, and regulatory compliance. The system records all movements and transactions linked to serial numbers, providing detailed audit trails. This capability enhances product authenticity verification and reduces fraud or counterfeiting risks.

- Explain the role of the ‘Product Information Management’ module in Dynamics 365 SCM.

The Product Information Management (PIM) module centralizes management of product data such as descriptions, classifications, pricing, and attributes. It ensures consistency and accuracy of product information across sales, procurement, and manufacturing processes. PIM supports variant configurations and product lifecycle management. Effective product data management improves operational efficiency, reduces errors, and enhances customer experience by providing reliable product details.

- What is the significance of ‘Batch Order’ processing in Dynamics 365 SCM?

Batch order processing groups multiple orders or transactions for collective processing to improve efficiency and reduce system load. In warehouse operations, batch picking allows picking multiple orders simultaneously, reducing travel time and labor costs. Batch processing also applies to production and invoicing cycles. This approach streamlines workflows and enables better resource utilization, improving overall throughput and reducing operational expenses.

- How does Dynamics 365 SCM manage demand forecasting inaccuracies?

Dynamics 365 SCM addresses forecasting inaccuracies by enabling continuous monitoring and adjustment of forecasts through real-time sales data and feedback loops. It supports collaborative forecasting with input from sales, marketing, and operations teams to improve accuracy. The system’s master planning integrates updated forecasts to adjust procurement and production plans accordingly. Using safety stock buffers and flexible replenishment strategies also mitigates risks from forecast errors.

- Describe how Dynamics 365 SCM supports lot tracking and recall management.

Lot tracking in Dynamics 365 SCM records and manages batches of products, linking them to production, inventory, and sales transactions. This traceability is essential for quality control and regulatory compliance. In case of defects, recall management processes use lot information to identify affected products quickly. The system facilitates communication, return processing, and corrective actions. This minimizes risks to customers and protects brand reputation by ensuring timely and effective recall execution.

- What is the function of ‘Resource Management’ in production?

Resource Management in Dynamics 365 SCM ensures optimal utilization of manufacturing resources such as machines, labor, and tooling. It involves scheduling, capacity planning, and maintenance management to avoid bottlenecks and downtime. The system tracks resource availability and performance, supporting decision-making for production scheduling. Efficient resource management leads to improved productivity, reduced costs, and timely order fulfillment.

- How does Dynamics 365 SCM handle international trade and logistics?

Dynamics 365 SCM supports international trade by managing compliance with customs regulations, tariffs, and trade agreements. It automates documentation such as bills of lading, commercial invoices, and certificates of origin. The system handles multi-currency transactions, duties, and taxes. Integration with logistics providers enables tracking shipments globally. These capabilities ensure smooth cross-border operations while minimizing delays and regulatory risks.

- Explain the benefits of integrating Dynamics 365 SCM with IoT devices.

Integrating Dynamics 365 SCM with IoT devices provides real-time visibility into supply chain operations. Sensors and smart devices can monitor inventory levels, equipment status, and environmental conditions such as temperature. This data enables proactive maintenance, reduces downtime, and ensures product quality during storage and transport. IoT integration enhances decision-making, increases operational efficiency, and supports automated workflows for a more responsive supply chain.

- How does Dynamics 365 SCM improve supplier performance management?

Dynamics 365 SCM improves supplier performance management by providing tools to track supplier delivery times, quality, pricing, and compliance metrics. The system collects and analyzes supplier data, enabling scorecards and performance dashboards. This visibility helps identify reliable partners and areas needing improvement. Automated alerts and workflows facilitate corrective actions and continuous improvement. Strong supplier performance management fosters better collaboration, reduces risks, and enhances overall supply chain resilience.

- What are the different types of demand that Dynamics 365 SCM can manage?

Dynamics 365 SCM manages several types of demand including independent demand, which arises from customer orders and forecasts, and dependent demand, which is generated based on the requirements of other items or finished goods. The system also supports forecast demand to anticipate future sales and safety stock demand for buffer inventory. By distinguishing these demand types, Dynamics 365 SCM enables precise planning and inventory control, ensuring that production and procurement align closely with actual and projected needs, thereby improving supply chain responsiveness and reducing excess stock.

- How is ‘Capacity Planning’ handled in Dynamics 365 SCM?

Capacity planning in Dynamics 365 SCM involves evaluating the available production resources—such as machines, labor, and work centers—to determine if they can meet planned demand within a given timeframe. The system assesses workloads, schedules operations, and identifies potential bottlenecks or underutilized capacity. It supports both finite and infinite capacity planning methods, allowing organizations to balance demand with resource availability. Effective capacity planning helps optimize production schedules, reduce lead times, and improve overall operational efficiency.

- Explain the process and importance of ‘Cycle Counting’ in warehouse management.

Cycle counting is a periodic inventory auditing process supported by Dynamics 365 SCM to maintain accurate inventory records without a full physical inventory. It involves counting subsets of inventory items regularly to detect discrepancies early. The system prioritizes counts based on item importance or transaction volume. Cycle counting reduces disruptions to warehouse operations and improves inventory accuracy, which is critical for effective order fulfillment, reducing shrinkage, and maintaining financial integrity in inventory reporting.

- What role does the ‘Transportation Management’ module play in Dynamics 365 SCM?

The Transportation Management module in Dynamics 365 SCM helps organizations plan, execute, and optimize inbound and outbound logistics. It supports carrier selection, route optimization, freight cost management, and shipment tracking. The module integrates with warehouse and inventory functions to coordinate loading and delivery schedules. It also manages transportation documentation and compliance requirements. By enhancing visibility and control over transportation activities, the module reduces costs, improves delivery performance, and enhances customer satisfaction.

- How does Dynamics 365 SCM handle product lifecycle management (PLM)?

Dynamics 365 SCM supports PLM by managing product data and processes throughout the product’s lifecycle—from design and development through production, maintenance, and disposal. It facilitates version control, change management, and collaboration across departments. Integration with quality management ensures compliance and traceability. PLM capabilities in Dynamics 365 SCM help accelerate time to market, improve product quality, and reduce costs by streamlining product development and manufacturing processes.

- Describe the use and benefits of ‘Kanban’ in Dynamics 365 SCM.

Kanban in Dynamics 365 SCM is a visual scheduling system used to control the flow of materials in production and replenishment processes. It uses signals such as cards or bins to indicate when inventory needs to be replenished. This pull-based system helps minimize inventory levels and avoid overproduction by producing only what is needed. Kanban supports lean manufacturing principles, improving responsiveness, reducing waste, and enhancing overall operational efficiency by synchronizing supply with actual consumption.

- What are ‘Product Dimensions’ and why are they important in Dynamics 365 SCM?